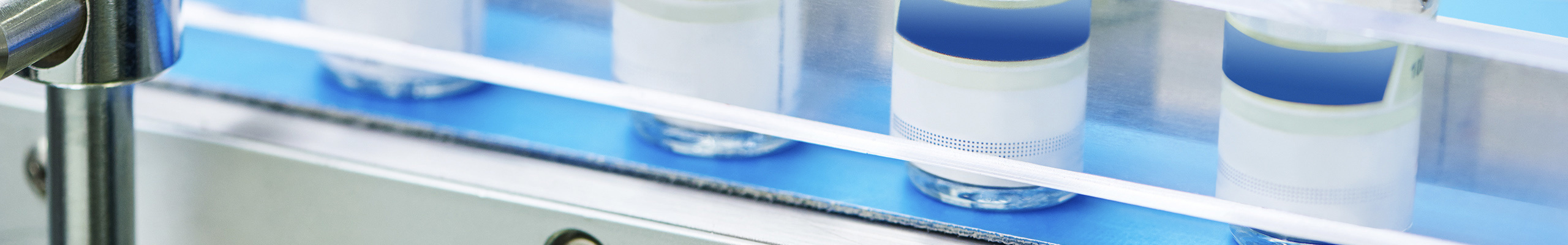

How to use food conveyor belt?

Food conveyor belt, also known as light conveyor belt, is a new generation of conveyor belt with new material structure. The special structure of the product belt determines its various excellent characteristics in actual use; such as: low elongation, good longitudinal flexibility, stable standard, low noise, long service life, and convenient equipment belt. Lightweight conveyor belts are widely used in high-demand assembly line operations such as cigarettes, wood processing, food, and electronics. Light conveyor belts can be divided into: ordinary conveyor belts, anti-static food conveyor belts, oil (acid and alkali) conveyor belts, high temperature food conveyor belts, non-toxic food conveyor belts, etc. Belts, corrugated edge food conveyor belts, anti-skid climbing conveyor belts, turning machine conveyor belts, perforated conveyor belts, lifting belts and other conveyor belts. The standard of light conveyor belt can be customized according to user needs.

① Appearance The different materials, thicknesses and markings of the appearance of the belt determine the adhesion, physical, chemical and mechanical properties of the belt. ② The strength layer of different raw material fabrics will largely determine the scale of belt application. The electrical conductivity, load-carrying capacity and elongation, electrostatic properties, flatness and suitability of the belt for edge turning are directly related to the fabric structure.

③ The bottom design of the bottom belt is to determine the degree of noise resistance, wear resistance of the belt and the habit of the belt to the support plate or support shaft.